EXPERIMENTAL ANCHOR INSTALLATION – DETERMINATION OF SIDE FRICTION BETWEEN GROUTED ANCHOR BOND LENGTH AND SOIL-ROCK FOUNDATION IN QUANG NINH

Minh Duc Group provides and installs trial anchors in the field of geotechnical engineering, including slope stabilization, foundation reinforcement, and other related applications.

1. Introduction

Project: Supply and Installation of Trial Anchors

Location: Quang Ninh Province

Year of Implementation: 2022

In the field of geotechnical engineering, testing plays a vital role in validating design calculations and evaluating the actual performance of structural systems. Through testing, engineers are able to verify safety factors, improve reliability, and ensure the overall quality of construction works. Permanent ground anchor systems are widely used in applications such as slope stabilization and foundation reinforcement. Today, in order to determine the design bearing capacity of ground anchors, it is essential for design engineers to evaluate the side friction between the anchor's bonded length (grouted bulb) and the surrounding soil or rock mass. As commonly known, the bearing capacity of an anchor embedded in soil or rock is calculated using the following general formula:

Where:

- D: Bonded length diameter;

- Lb: Bonded length of the anchor;

- tult: Maximum side friction capacity of the anchor’s bonded zone with the surrounding ground.

Typically, the side friction values are obtained by referencing existing tables. However, these values often vary within a wide range, which poses challenges for engineers and frequently leads to conservative design choices favoring safety. As a result, the predicted bearing capacity of the anchor may not accurately reflect the actual conditions.

For the Ha Long Marina project, a distinctive characteristic is the presence of numerous unpredictable karst cavities beneath the foundation. This project includes both permanent ground anchors and bored piles for high-rise building foundations. Due to concerns about deep karst cavities beneath the piles, the design consultant reduced the end bearing capacity of the piles and increased the reliance on shaft friction resistance. Therefore, the shaft friction parameter is critically important for the project.

To determine the side friction value between the anchor and the surrounding soil accurately, ensuring the project’s reliability and safety, Minh Duc Group was commissioned by the investor to carry out trial anchor installation and testing to identify the side friction resistance between the anchor bond length and the soil at the Quang Ninh site.

2. Fabrication and Installation of Trial Anchors

The experiment was conducted on six anchors located at different positions within the project site.

Anchor characteristics and specifications:

- Anchor length: from 40 to 45 meters

- Number of strands: 12

- Diameter of the bonded length (grouted bulb): 150 mm

- Bonded length varies depending on each anchor, with lengths of 4 meters and 6 meters.

A special feature of the anchors is the incorporation of a grout length control device to ensure the bonded length matches the design specifications. The grout stopper was fabricated together with the anchor to precisely control and restrict the grout within the designed bonded length.

The anchors were manufactured at Minh Duc Group’s specialized workshop. The testing process was conducted under the supervision and inspection of the Investor. The strands were threaded through the grout stopper so that the stopper is positioned in the middle of the strands. The grout stopper was bonded to the strands by injecting epoxy resin inside the stopper as per the design requirements. The grout bag was connected to the grout stopper by steel bands according to the approved design. The grout injection pipes for the grout stopper, anchor bonded length, and air vent pipes were connected to the grout stopper in strict compliance with the approved design.

The images of the trial anchors fabricated with the grout stopper for the bonded length are shown below.

1. Trial Anchor Structure

2. The anchors were manufactured at Minh Duc Group’s dedicated fabrication workshop

3. The investor carried out quality checks on the anchors manufactured at Minh Duc Group’s workshop

4. The grout stopper underwent trial grouting at the construction site.

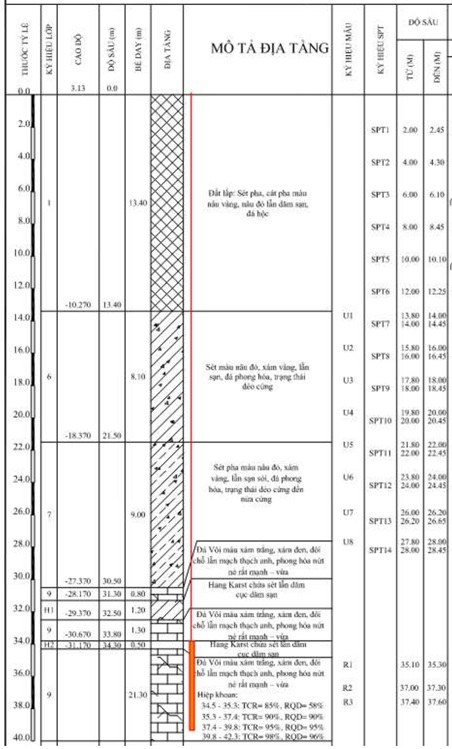

Geological Information: The geological profile of the area consists of a thick layer of soft clayey soil at the upper strata. Beneath this layer lies the limestone bedrock. The anchor’s bonded length is installed within the limestone layer.

5. Geotechnical Column for the Project

6. Trial anchor installation at the construction site

Grouting is a critical task in the project. The side friction results are only reliable when the grout fully fills the designed bonded length without overflowing beyond it, which would artificially increase the bonded length and compromise the accuracy of the measurements.

During the grouting process, the contractor strictly controlled and measured the volume of grout injected to accurately calculate the actual grout volume placed inside the anchor bond zone. The actual grout volume was then compared with the designed grout volume and reported to the Project Management Board and the consulting unit. In practice, the grout stopper worked effectively, as evidenced by the injected grout volume closely matching the expected grout volume corresponding to the predetermined bonded length. Furthermore, the additional grout injected afterward was equal to the grout discharged through the pipe below the grout stopper, indicating no grout loss due to upward overflow.

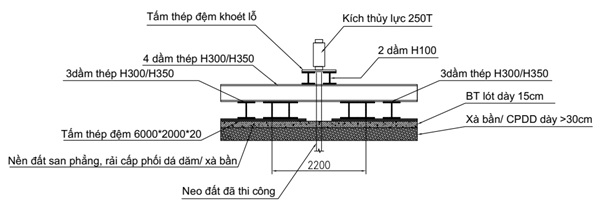

The experimental setup diagram and images of the trial anchor tension testing are as follows:

7. Trial anchor tension testing

3. Test Results

The testing was independently supervised by a third-party monitoring unit, and the investor also closely followed the entire installation and anchor tension testing process to ensure that the test results accurately reflect the actual performance of the anchors.

The trial anchors were tensioned to a maximum load of approximately 240 tons, which is close to the critical strength of the cable material. The results obtained represent the side friction values between the anchor and the surrounding soil. These friction values will be evaluated and compared with current relevant standards. The data are highly valuable for design purposes and for assessing the reliability and quality of the construction works. Additionally, the results can serve as a reference for design calculations in similar projects.

The quality of prestressed cable installation was ensured throughout the process. Moreover, the results also reflect the quality of the deep anchor drilling works in complex and weak soil-rock strata, demonstrating Minh Duc Contractor’s capability and expertise.