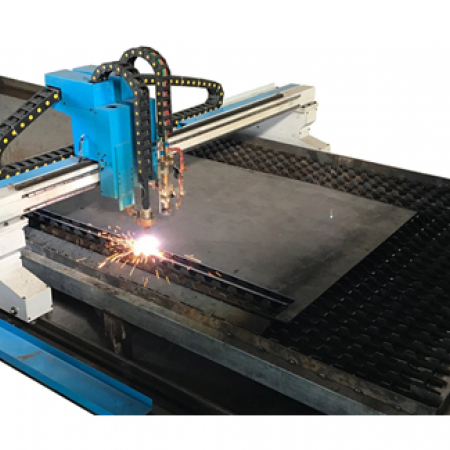

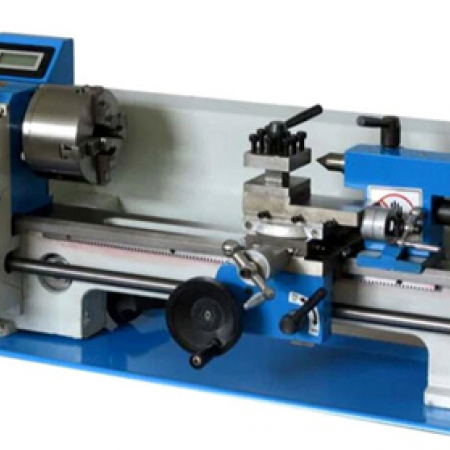

MACHINING MACHINERY

Products can be ordered according to the requirements.

With the motto of quality first, we are committed to bringing the best quality products and meeting the best schedule

Details

In order for products to meet standards and have uniform quality, we apply the following basic steps:

Step 1: Design drawing

Study detailed drawings, research the working function and detail classification, the technical requirements to be achieved, the technology when manufacturing the part.

Step 2: Determine the type of production

There are 3 main types of production:

- Single production

- Mass production

- On-demand production

Step 3: Select the workpiece and the method of making the workpiece.

- In order to manufacture a machine part that meets the technical requirements and economical criteria, the designer of the technological process must choose a method of making workpieces and determine the appropriate size of the workpiece.

Step 4: Determine the order of operations, steps... , choose the fixture diagrams for each operation, offer different technological options for manufacturing details.

- When designing the technological process for machining machinery parts, it is necessary to determine the appropriate order of operations and steps so that the complete machining cycle of a part is the shortest, ensuring the best processing quality.

Step 5: Select the device.

- Proper selection of equipment, tools, and fixtures has a great influence on the quality, productivity and cost of detailed machining machinery. Therefore, when designing a detailed machining technology process, it is necessary to analyze and consider carefully when determining and selecting equipment, tools, and fixtures...

Step 6: Determine the amount of machining residue (the metal layer to be removed) for the operations and steps.

- After offering the technological options for detailed machining, it is common to compare the options to choose the most efficient and reasonable one in the given production conditions. From the selected technological process plan, documents and technology sheets will be developed to guide production and serve the management, monitoring, calculation...

Product Reviews