Overview of Slope Stabilization

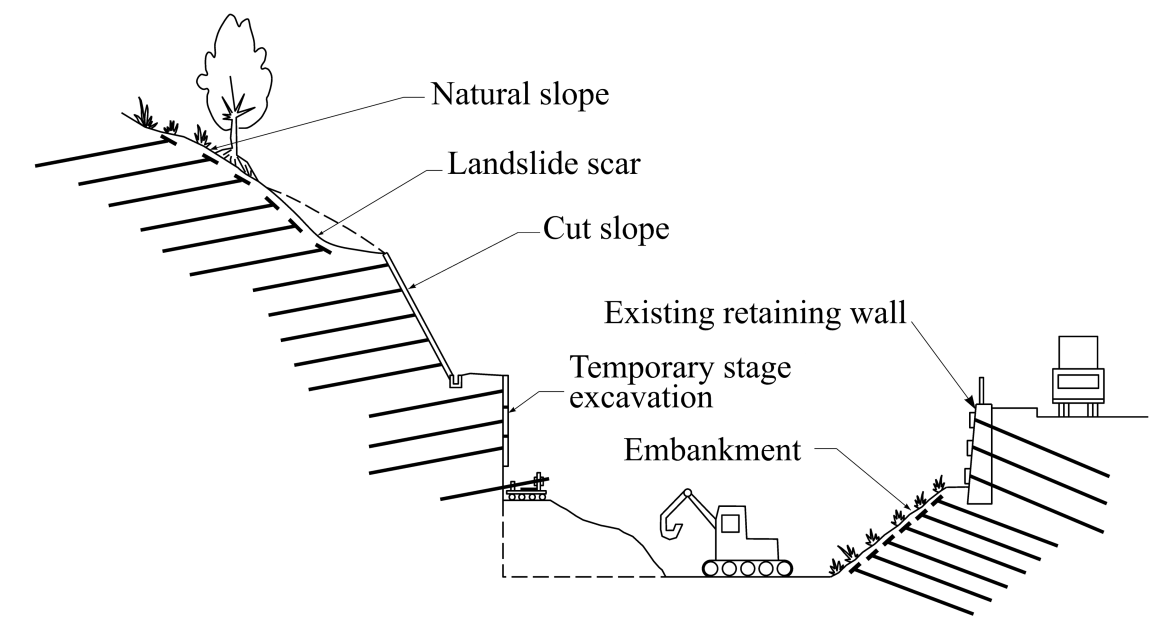

Slope stabilization is a general term used for soil/rock slopes that have failed or are at risk of failure and need to be reinforced to meet safety requirements. Based on assessment and analysis, a decision will be made on whether stabilization should be carried out. Geological hazards occur in many different forms and scales. Once a landslide has taken place, some slopes can be stabilized, while others cannot or should not be reinforced. In cases where stabilization is not feasible, alternative solutions (such as constructing a bridge) are applied to avoid unstable or landslide-prone areas.

Landslide mitigation and slope stabilization are specialized geotechnical challenges that intersect with various other fields of construction. Therefore, engineers involved in the design and implementation of slope stabilization must possess strong interdisciplinary knowledge, solid technical foundations, and, most importantly, practical experience

For evaluating and maintaining slope stability, comprehensive site investigation, data collection, and thorough analysis are essential. Slopes must be assessed under the most unfavorable conditions to evaluate their stability and to propose appropriate solutions that meet both technical and economic requirements.

At present, the company provides a wide range of slope stabilization solutions for both cut slopes and fill slopes, tailored to the diversity and complexity of real-world conditions as well as the specific characteristics of construction sites. The company offers solutions for both deep and surface stabilization, applicable not only to soil slopes but also to rock slopes, including cases with complex interbedded soil and rock formations. Some of the main solutions can be outlined as follows.

Soil Nails

Soil nailing technology is widely used today in Vietnam and around the world due to its adaptability to various construction conditions, demonstrating both technical and economic efficiency compared to other methods. It is applied to enhance the stability of slopes, retaining walls, and deep excavations in almost all types of projects, including transportation, civil and industrial, as well as hydraulic projects. Notably, soil nailing can be applied to existing slopes, cut slopes, and fill slopes. Its advantages include:

- It can be applied in confined and difficult construction conditions, as the equipment required is small in size and relatively simple.

- It adapts well to varying geological conditions; the nail length and position can be easily adjusted to suit actual site conditions thanks to the simple design, which allows for extensions and connections.

- More cost-effective compared to traditional methods.

- Minimal impact on surrounding areas and the environment.

The development of soil nailing can be traced back to rock bolting technology used in tunneling (Geoguide 7). In Western countries, soil nailing has been applied for slope stabilization, excavations, and retaining walls since the 1970s; in Japan and Hong Kong, its use began in the 1980s (Geoguide 7, M. Hirano). In Vietnam, to the author’s knowledge, there is no documented record of when soil nailing was first introduced. However, according to the author’s observation, the application of soil nailing started to become common in construction projects around 2016–2018. Up to now, soil nailing has been widely adopted in most slope stabilization projects in Vietnam and has demonstrated its effectiveness in many cases.

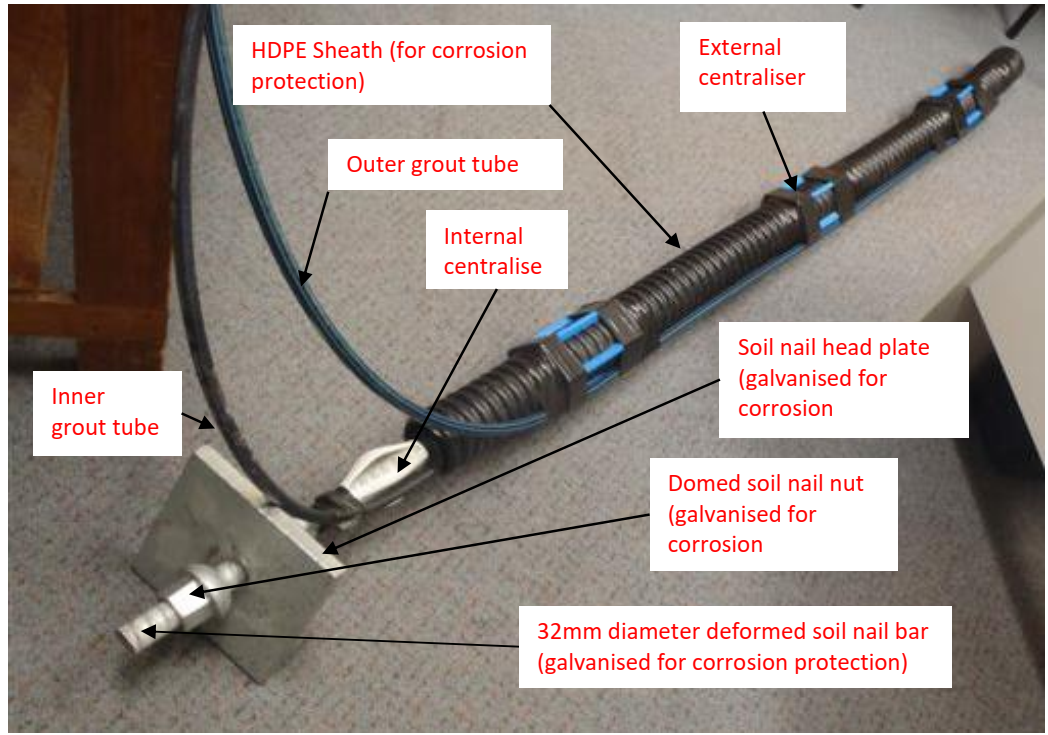

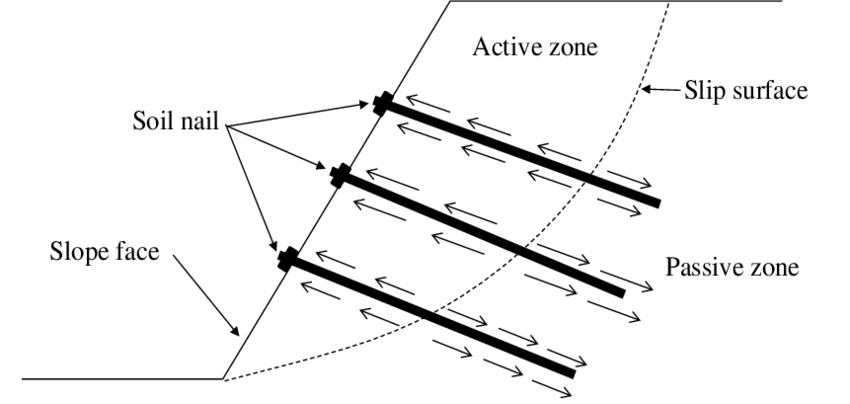

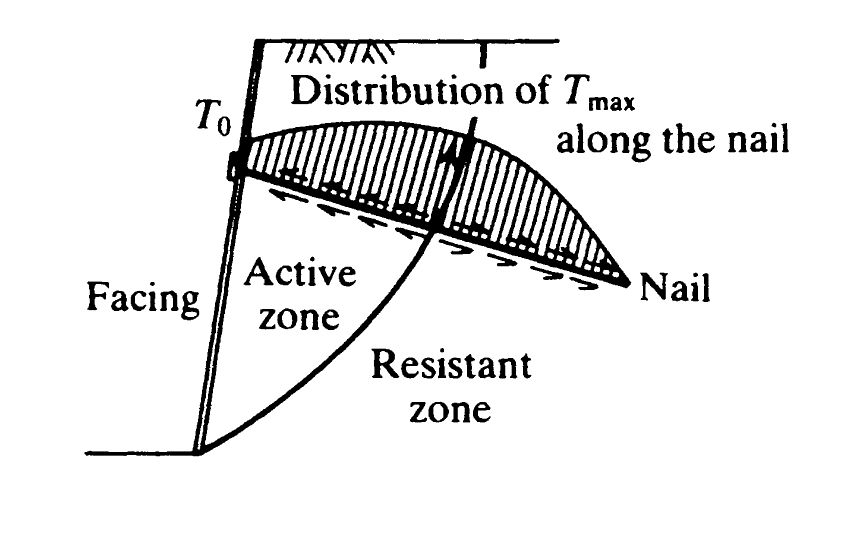

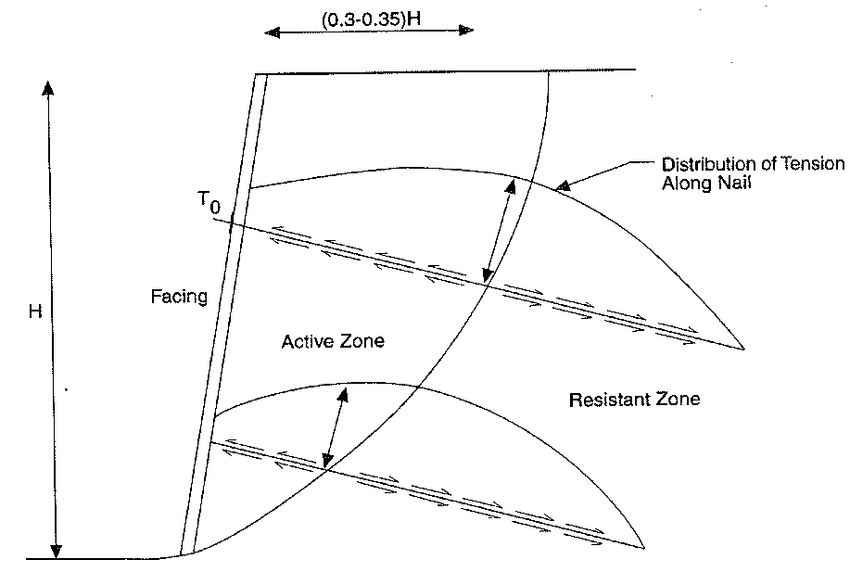

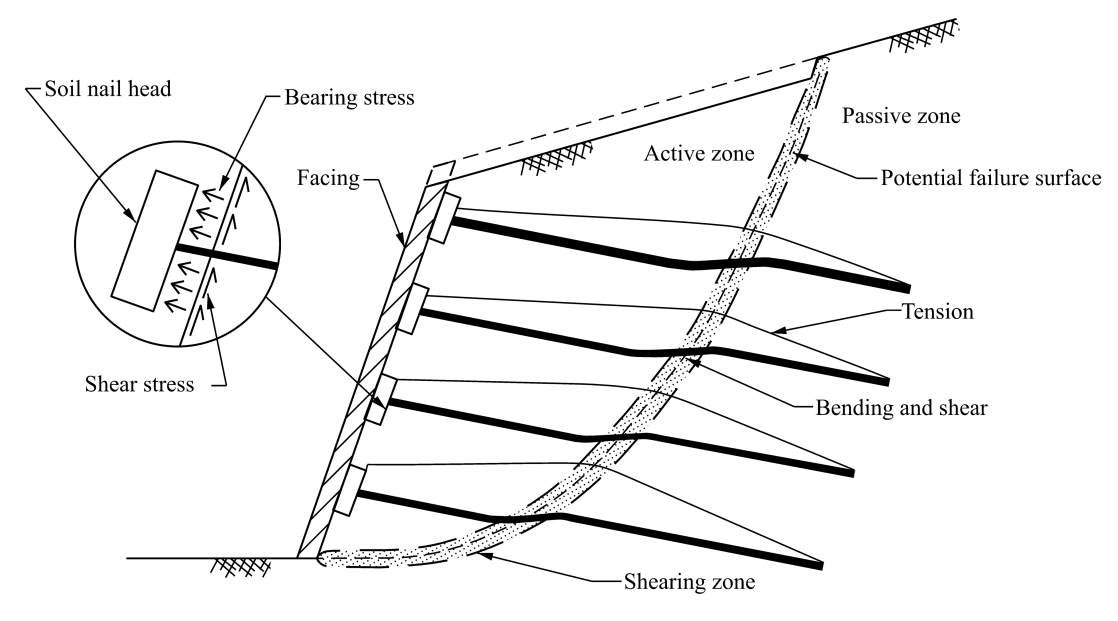

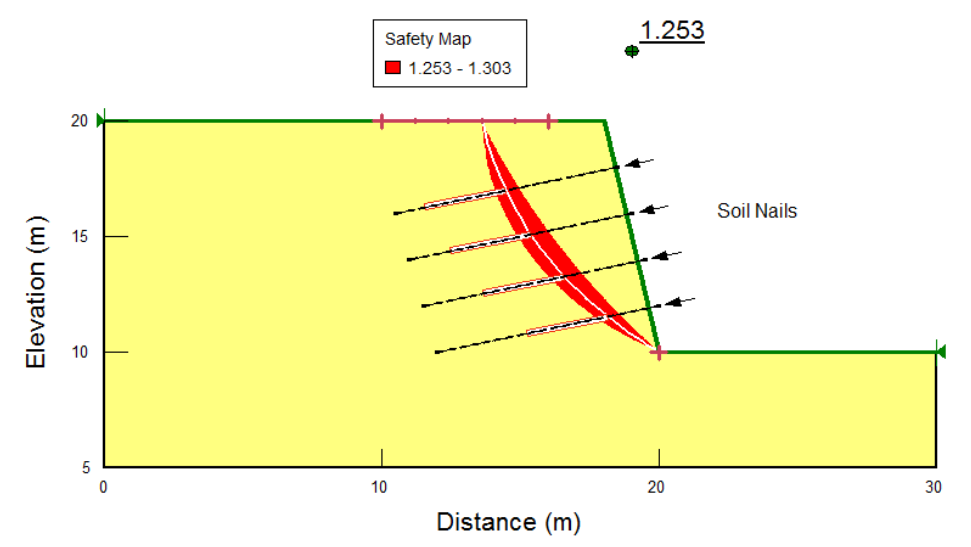

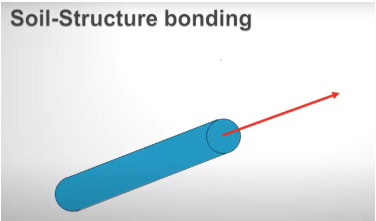

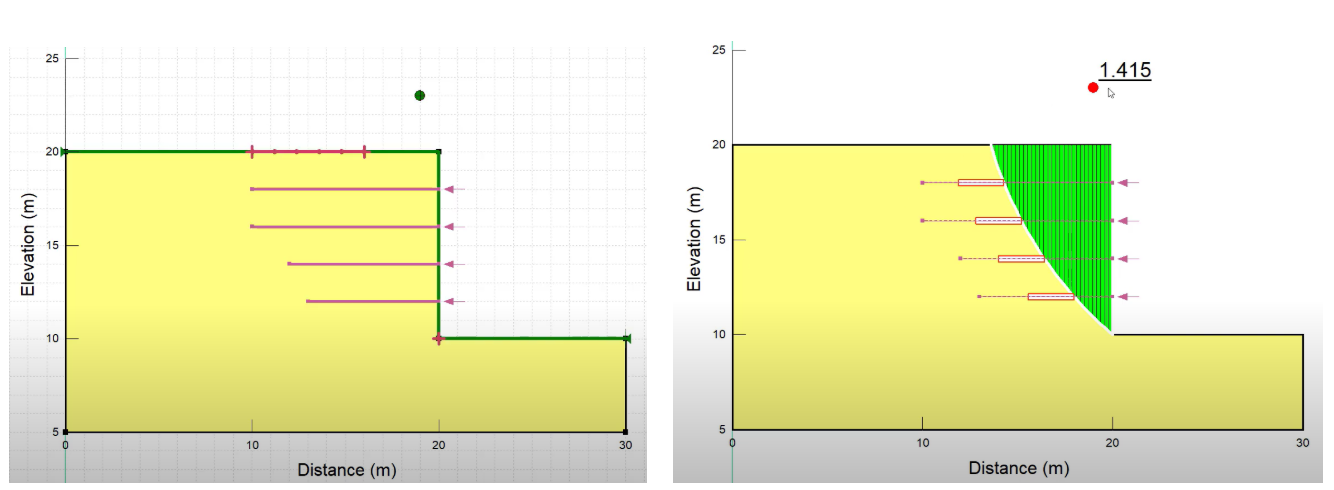

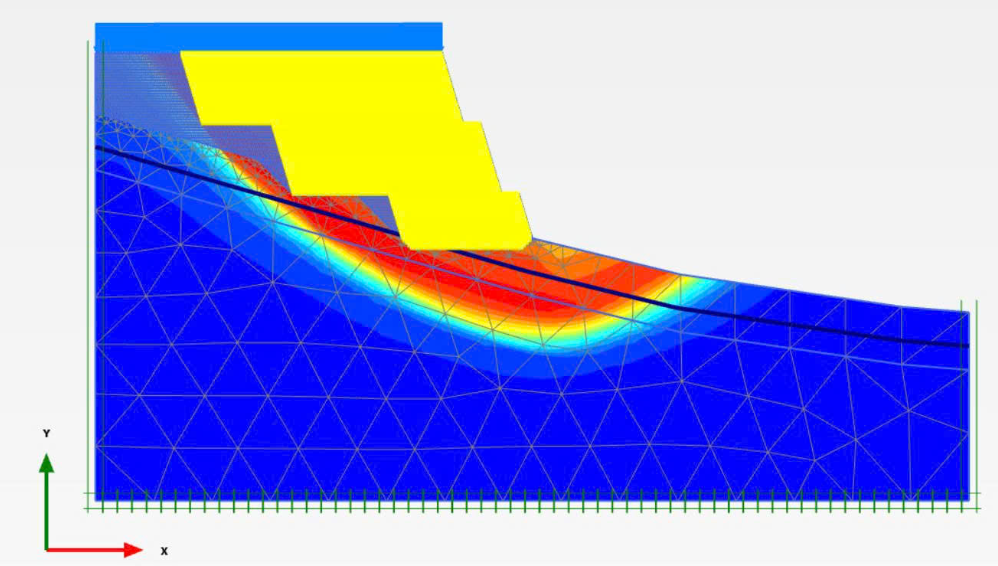

Principle of slope stabilization using soil nails: at the interface between the soil nails and the surrounding soil mass, interaction forces are generated. These interactions provide resistance against the sliding of the soil mass. Such interactions only develop when slope displacement occurs; therefore, soil nails are considered a passive reinforcement system. Specifically, the interaction forces are illustrated in the figure below. The interaction between the nails and the soil forms in two zones: within the sliding mass and within the stable ground beyond the slip surface. Depending on the characteristics of the slope failure (large or small, shallow or deep), the soil nail design must ensure appropriate parameters such as the number and depth of nails to achieve the required slope deformation control and stability factor.

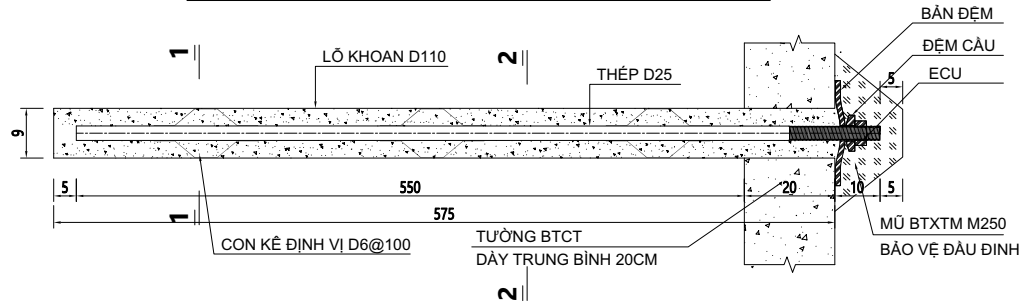

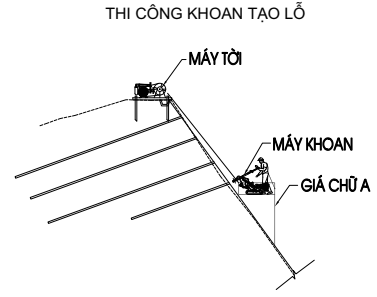

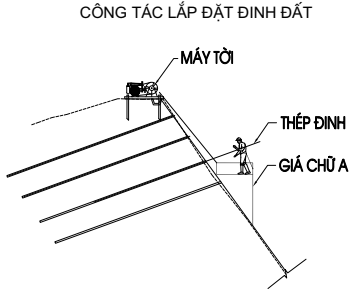

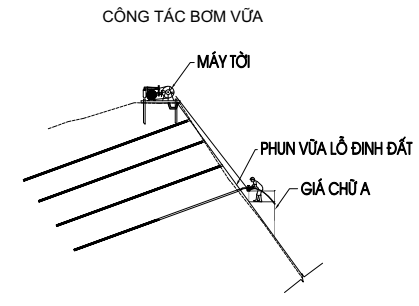

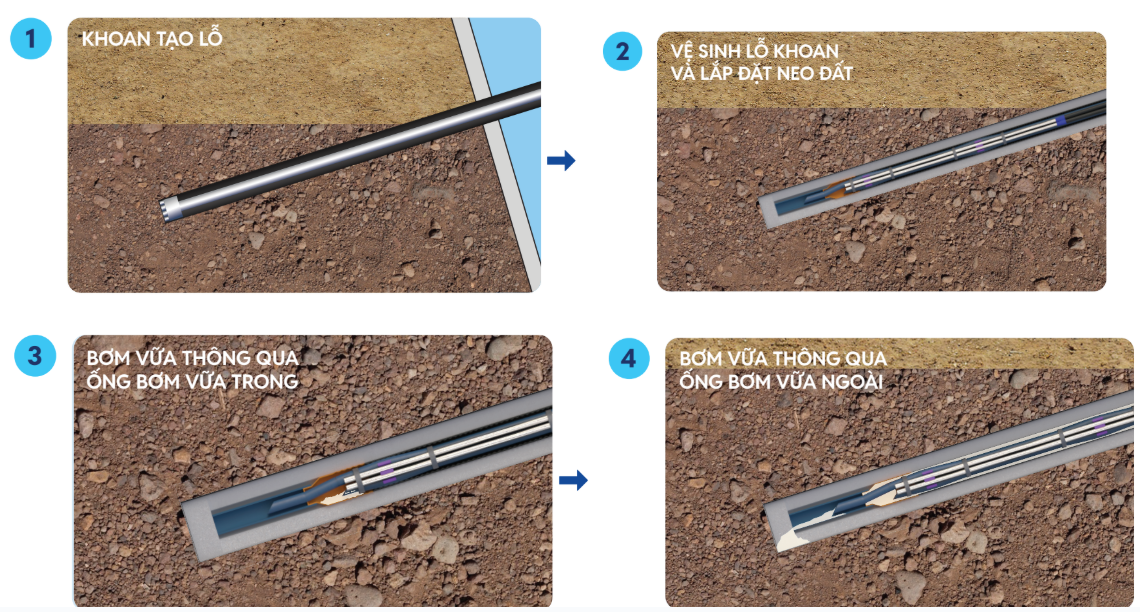

Soil Nailing Construction Procedure

Soil nails are generally installed from the top down. In Vietnam, boreholes are typically drilled using a combination of rotary-percussion drilling, followed by air flushing to remove soil and rock cuttings. Once the borehole is completed, the steel nail bar is inserted, and self-flowing grout is injected to completely fill the hole.

Common Applications of Soil Nailing: Soil nailing is applied for stabilizing cut slopes, natural slopes, temporary excavations, existing retaining walls, and more.

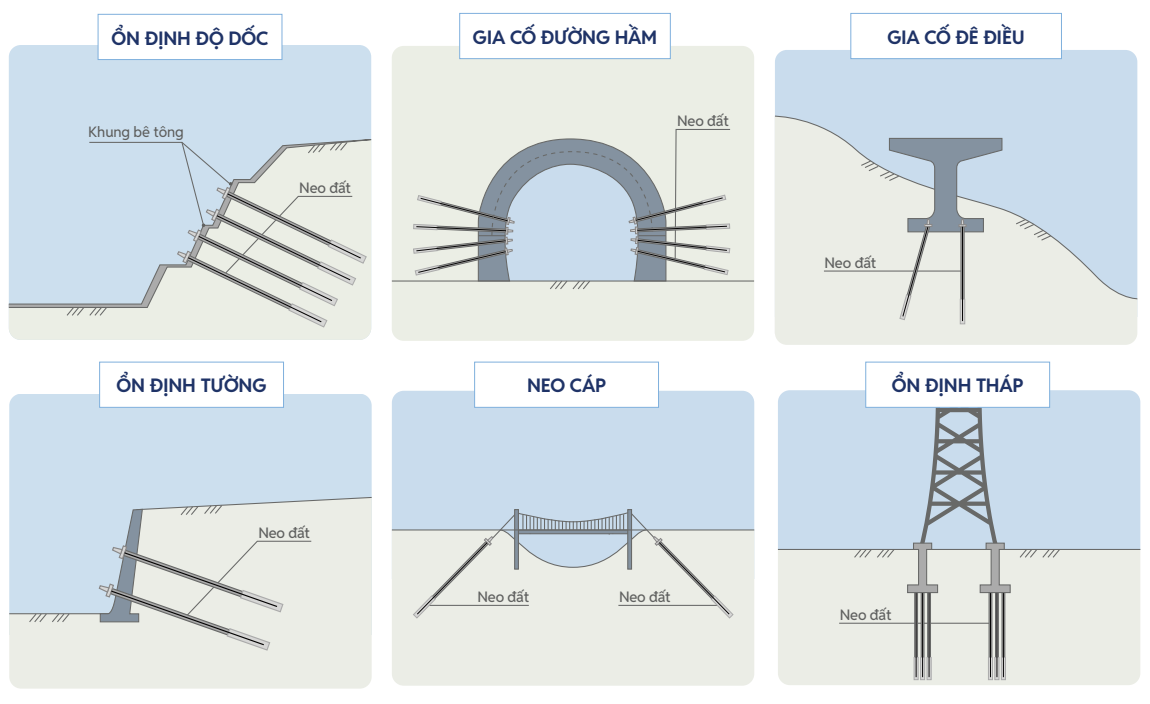

Ground Anchors

Ground anchors come in various types, which can be generally classified into two categories:

- Permanent Anchors

- Temporary Anchors

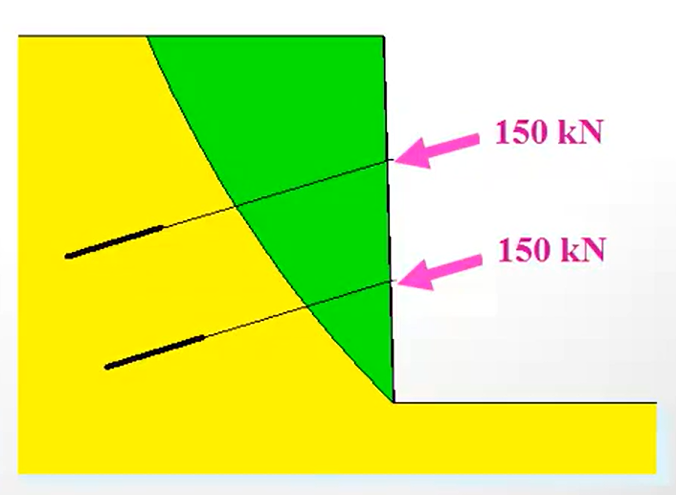

Temporary anchors are typically used in temporary works such as foundation pit excavations. Once construction is completed, the anchors are either removed or cut off. In slope stabilization projects, however, the structures remain in place for many years, and the anchors must serve throughout the entire service life. Therefore, permanent anchors are used in slope stabilization projects. The working principles of temporary and permanent anchors are quite similar. However, in detailed design calculations, there are certain differences, such as safety factors and structural requirements. Compared to rock bolts and soil nails, ground anchors have a higher load-bearing capacity and are thus often employed for stabilizing larger sliding masses.

Anchors are critical structural elements and involve significant costs. Any failure or design error may affect the safety and overall stability of slopes and retaining walls. Therefore, all parameters such as length, spacing, and density must be carefully calculated to ensure compliance with design requirements.

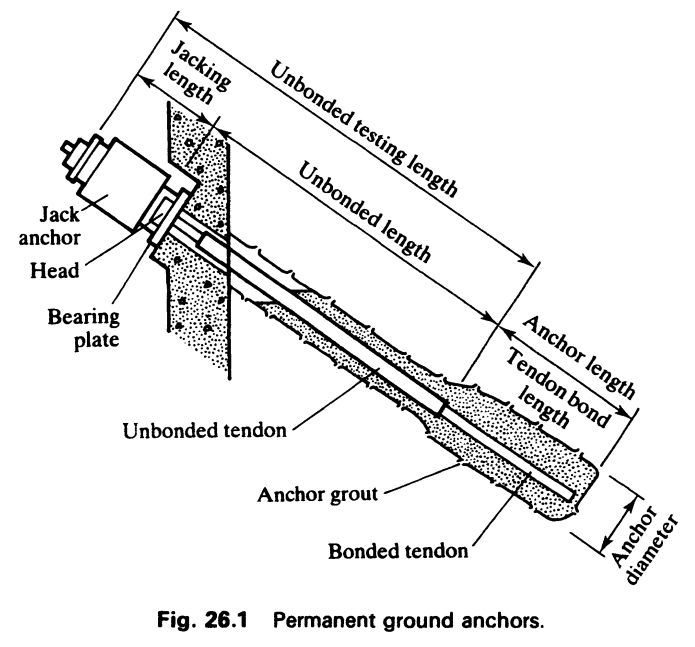

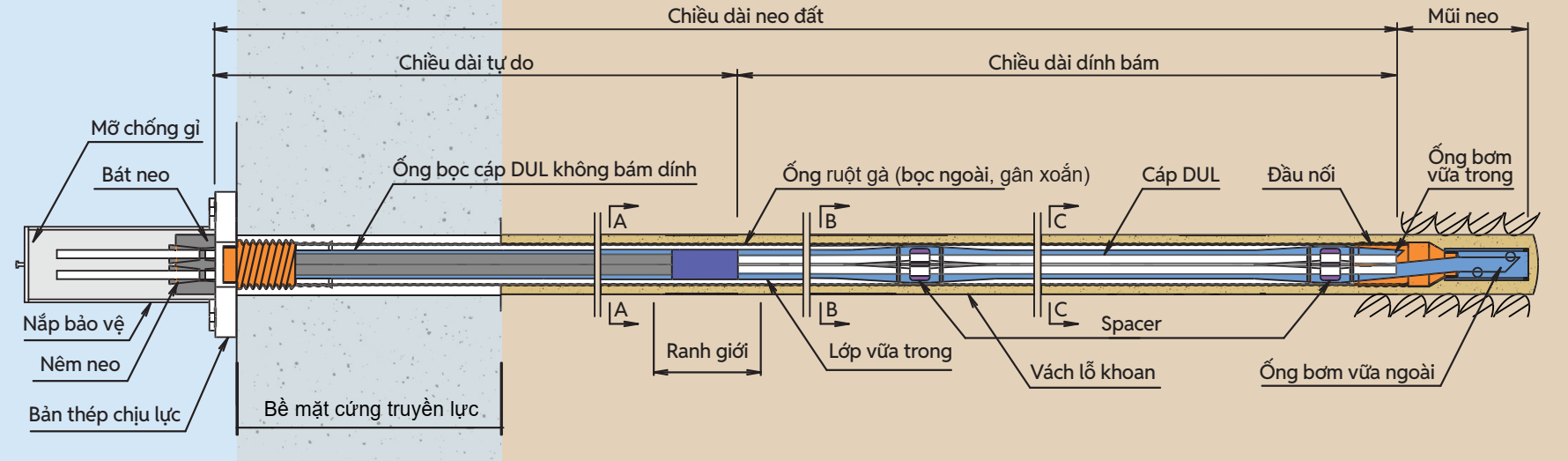

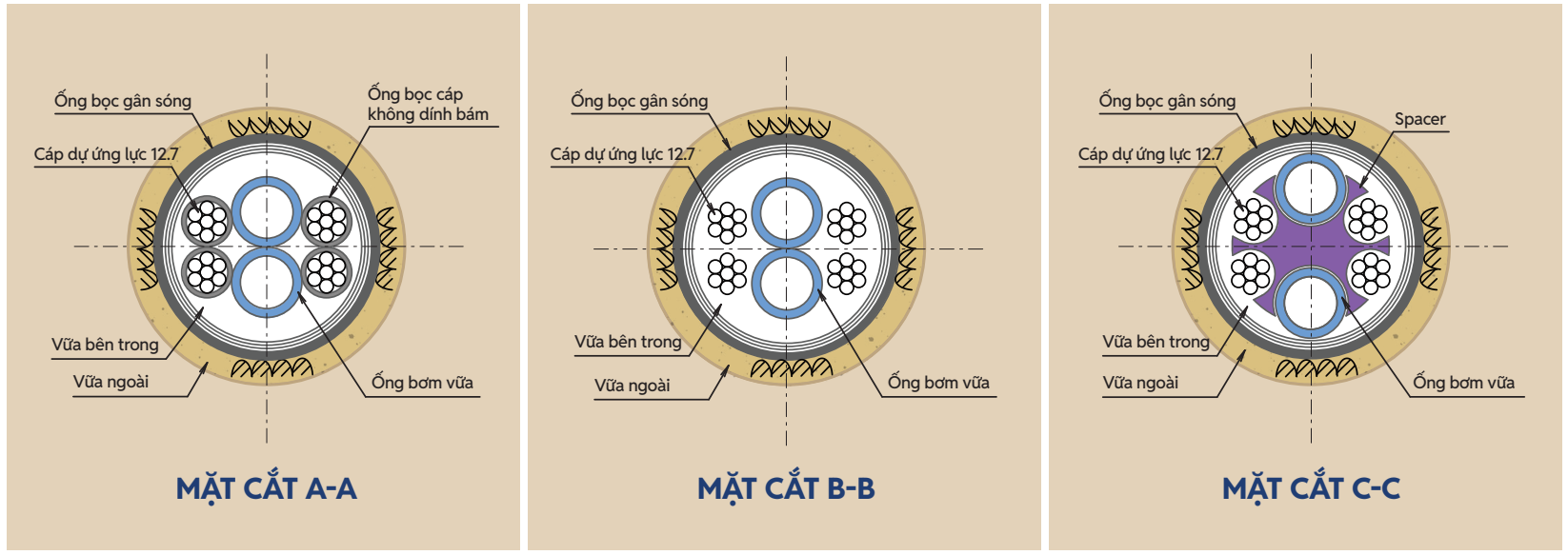

A typical permanent anchor has the following structure: it consists of three main parts — the anchor bond length, the free length, and the anchor head. The anchor tendon is made of high-strength steel. For permanent anchors, the required protective cover thickness is greater.

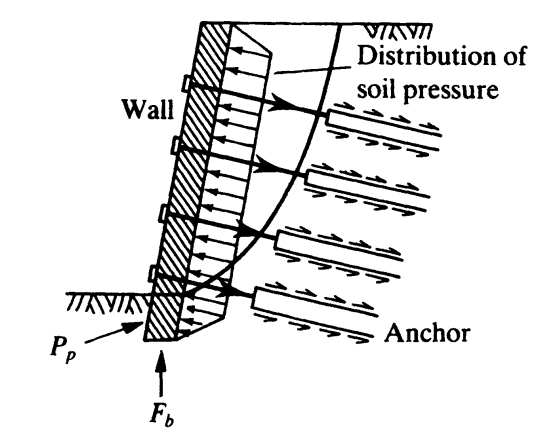

Working Principle + Illustration: After the anchor is installed and sufficient time has been allowed for the materials to reach their required strength, the anchor is prestressed to generate tensile force. This force is balanced by the interaction between the anchor bond length and the surrounding ground, with the bond zone designed to lie outside the potential slip surface. The prestressing force is transferred to the ground mass through a stiff facing plate, thereby resisting soil mass movement. The principle is illustrated in the figure below.

Contruction Sequence of ground anchors:

Common applications of prestressed ground anchors:

![1]() Reinforced soil wall

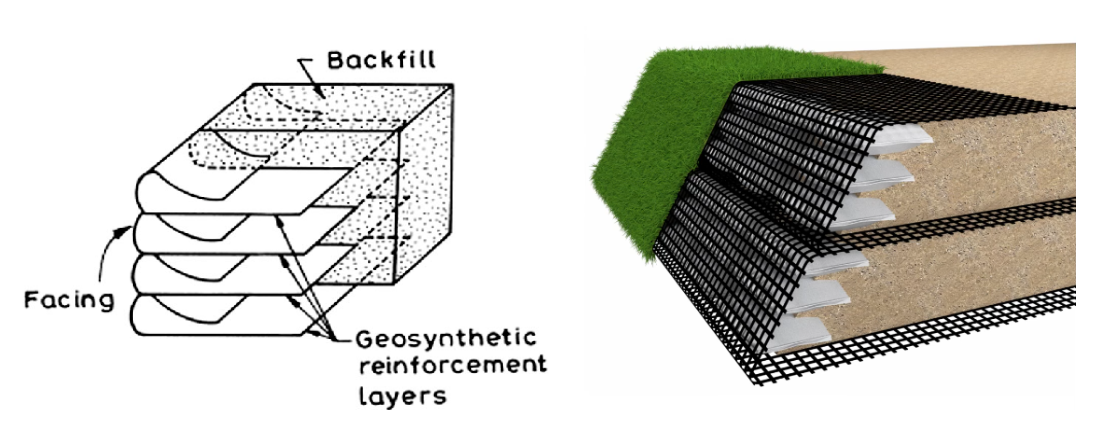

Reinforced soil wall

This can be considered a green solution, both environmentally friendly and meeting economic and technical requirements. Similar to how concrete requires reinforcement (usually steel, hence called reinforced concrete), soil has very poor tensile strength and therefore needs reinforcement to enhance its load-bearing capacity.

The working principle of a Mechanically Stabilized Earth (MSE) wall is based on the combination of backfill material and reinforcement layers to form a stable soil mass acting as a unified “soil–structure block.

1. General principle

- Soil generally has good compressive strength but very poor tensile strength → when the soil is steep or near vertical, the backfill behind the wall tends to slide or collapse because the tensile stress exceeds the soil’s capacity.

- Reinforcement layers (typically geogrid, geotextile, flat steel, or composite strips) are placed horizontally within the fill soil, helping to transfer and resist tensile forces on behalf of the soil.

- When the soil and reinforcement are compacted together, they form a bonded mass with much greater compressive, tensile, and shear strength than the original soil.

2. Load-bearing mechanism

- External loads (soil self-weight, vehicular loads, wind, earthquakes, etc.) → generate sliding and overturning forces in the soil mass behind the wall.

- The reinforcement layers anchor into the soil mass, transferring tensile stress from the tensioned zone to a more stable zone through friction or mechanical interlock between the soil and the reinforcement.

- This combination:

- Reduces active earth pressure on the wall face

- Prevents excessive deformation and failure due to sliding

- Enhances the overall stability of the wall

3. Main components

- Reinforced soil mass – provides compressive resistance.

- Reinforcement layer – resists tension, transfers forces, and locks the soil in place.

- Wall facing – protects the soil from erosion and maintains the shape (can be rigid: concrete panels, or flexible: mesh, gabions, turf mats…).

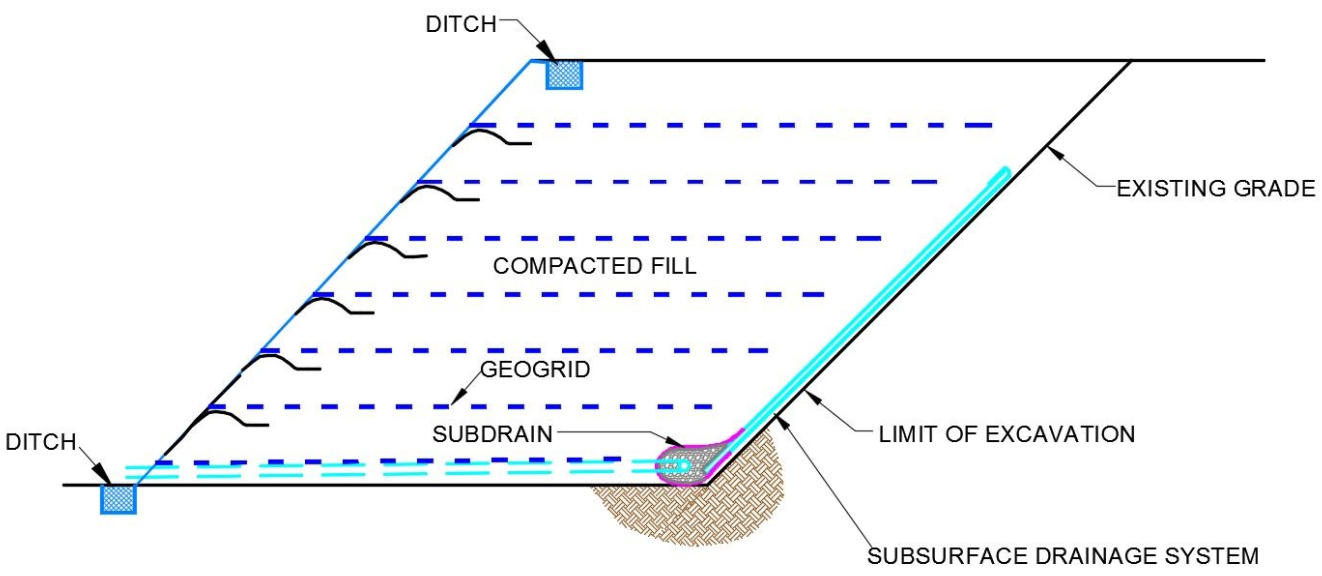

Surface stabilization solutions

Slopes are structures that, due to their characteristics such as soil conditions, soil type, natural slope, groundwater level, and local climate, often experience problems like sliding, weathering, and erosion. Among these, surface erosion is always present under external influences such as rain and flooding. Continuous surface erosion can eventually lead to major slope failures.

In addition, sometimes the slope surface is required to be vegetated to ensure aesthetics and environmental friendliness, avoiding excessive concreting.

Below are some factors related to slope erosion:

- Rainwater infiltrates the soil or flows over the surface, so this factor must be carefully considered from the very beginning of any construction project.

- Slope angle of the soil or rock slope.

- Surface runoff

- Formation of rills and small channels

- Soil porosity and permeability

- Solar radiation intensity, temperature fluctuations, and seasonal changes: dry season and rainy season.

To design structures for controlling surface erosion on slopes, it is necessary to analyze geological, geotechnical, environmental, and hydrological conditions in order to predict how the slope will behave after construction. Below, two main reinforcement materials that the company has successfully applied to prevent slope erosion in real projects are introduced. It is important to emphasize that these materials must be considered from the very beginning of construction, rather than merely as remedial measures. The key point is that slope protection materials should be integrated into the initial design, not applied only after signs of erosion or collapse appear.

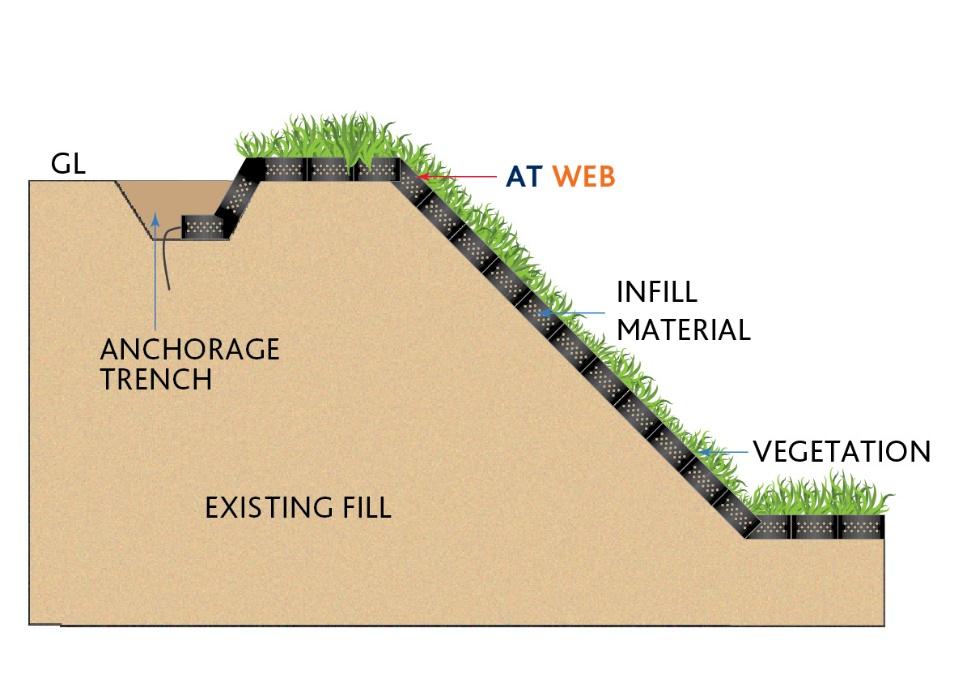

1. Geotechnical Cell

A geotechnical cell is a group of three-dimensional (3D) cells made of high-density polyethylene (HDPE), reinforced with polyester fibers. They are manufactured from HDPE strips arranged in multiple rows and connected in a staggered pattern along the length, forming a honeycomb-like structure when expanded perpendicular to the surface. The cells are then filled with soil and planted with grass to vegetate the slope. This solution prevents erosion, is environmentally friendly, and avoids structural issues caused by the erosion of bare soil layers.

Advantages of geotechnical cells:

- Reduces sediment-laden runoff and slope failures on highways, roads, and railways.

- High tensile strength and strong adhesion to the slope surface.

- Used as a support layer for slopes intended for planting, as they promote the development of vegetation cover.

- Not only is it a more cost-effective solution, but it also reduces environmental impact by limiting the use of concrete and steel compared to traditional formwork.

- Quick to construct and does not require heavy machinery.

- Made from recycled, non-toxic materials.

- Highly durable due to UV resistance and oxidation protection of the geosynthetic materials.

![1]()

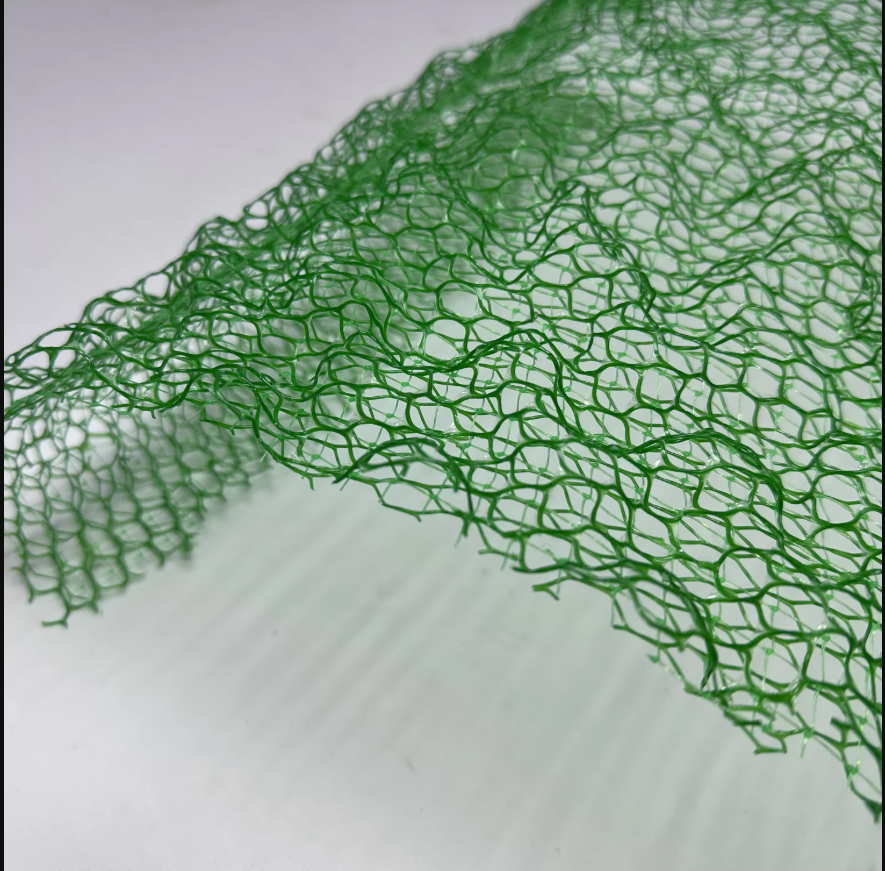

2. Erosion control mats / coir mats

Functions of erosion control mats / nets:

- Prevents the slope surface from wind and rain erosion, and stops soil washout caused by rainwater and runoff.

- Forms a protective layer for vegetation mats.

- Replaces concrete or precast concrete panels, allowing coverage with a green, environmentally friendly, and sustainable solution.

![1]()

![1]()

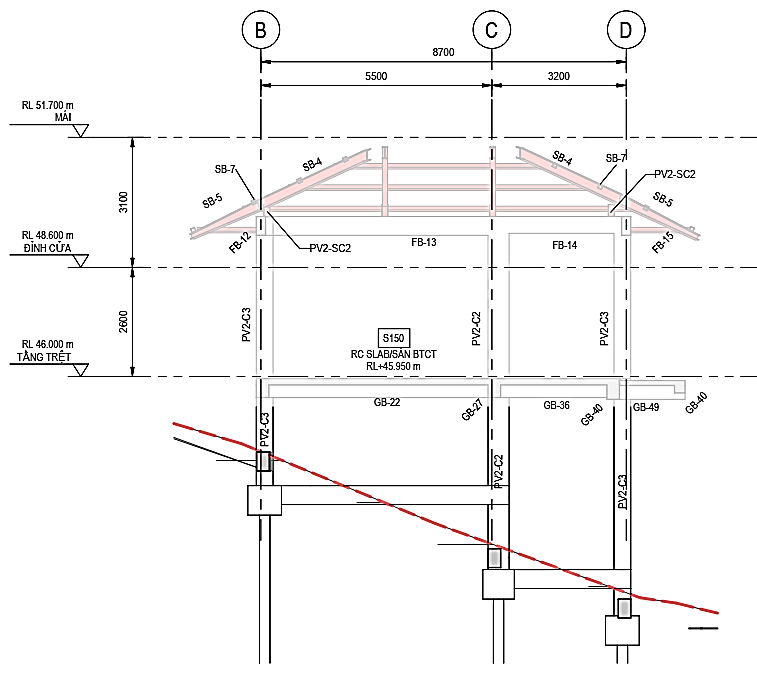

Micropile

There are many types of piles in construction, which can be classified based on the pile material, shape, or construction method. Each type has its own characteristics and specific applications. Micropiles are small-diameter piles commonly used for slope stabilization and as foundations for structures on slopes where shallow foundations pose significant risks. Micropiles have the following characteristics:

- Piles with a small diameter, typically less than 300 mm.

- Suitable for steep hillsides, complex geology, and limited construction space, where other types of piles, such as driven or bored piles, are unsuitable or very difficult to apply. This is because micropiles have a small diameter, allowing compact construction equipment to access steep or mountainous areas for installation.

- Piles can be inclined or angled in any direction.

Micropiles also come in various types. For larger diameters, steel casing can be used with cast-in-place concrete, while smaller diameters may use only steel bars grouted in place. In design, engineers flexibly combine micropiles with other structural elements such as walls, soil nails, and anchors to create an efficient working system.

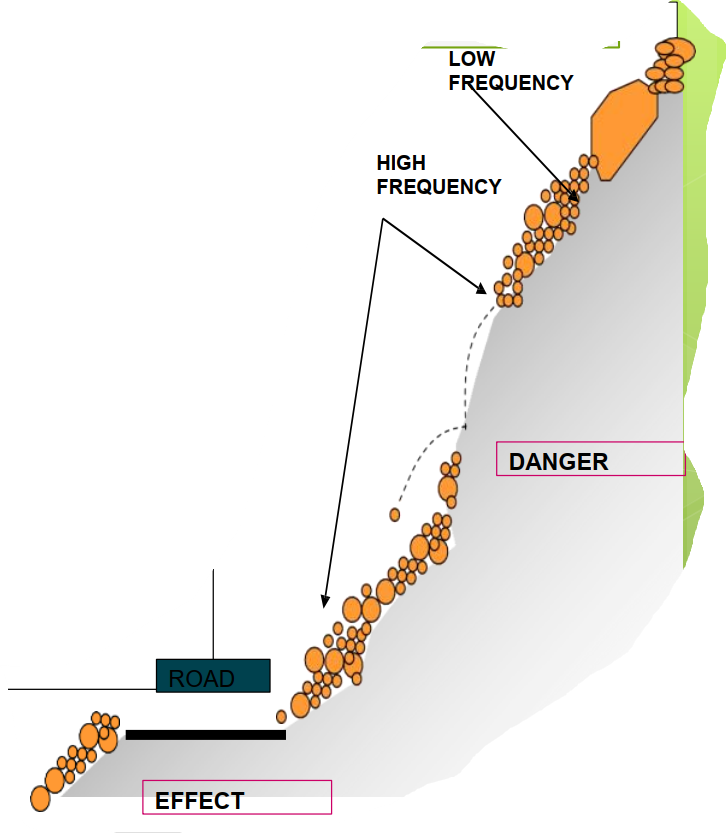

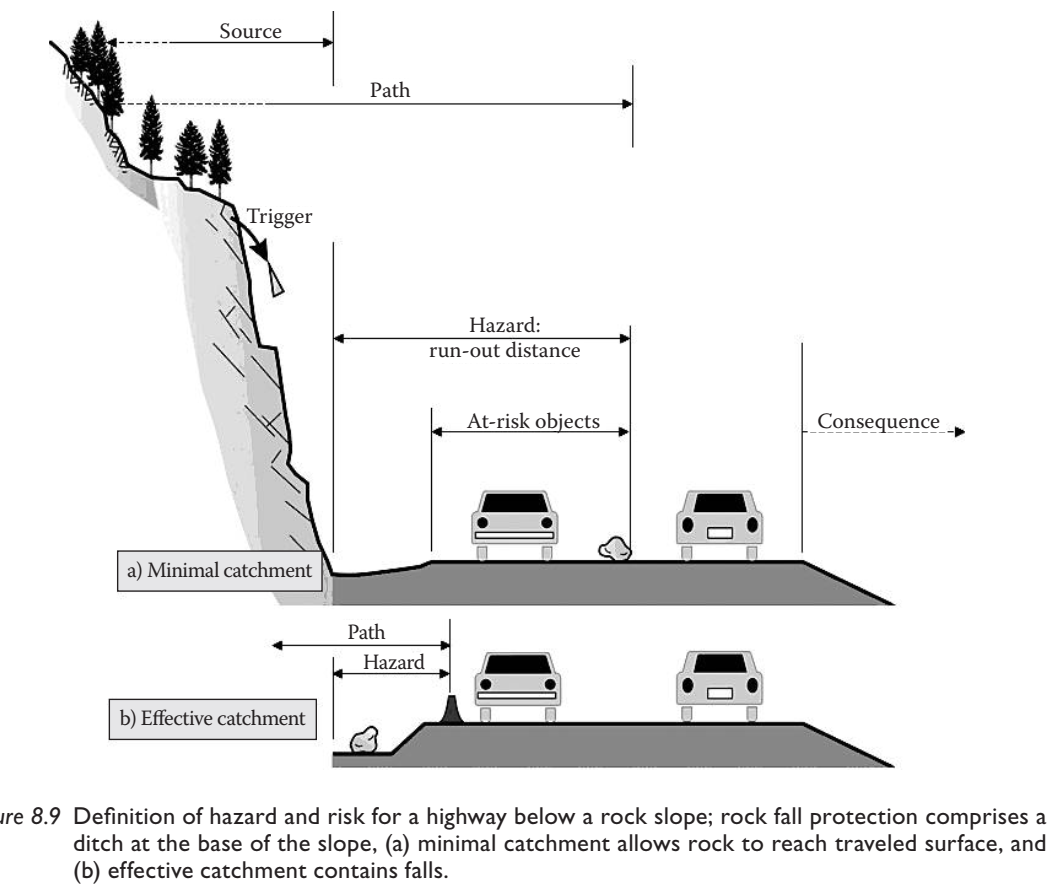

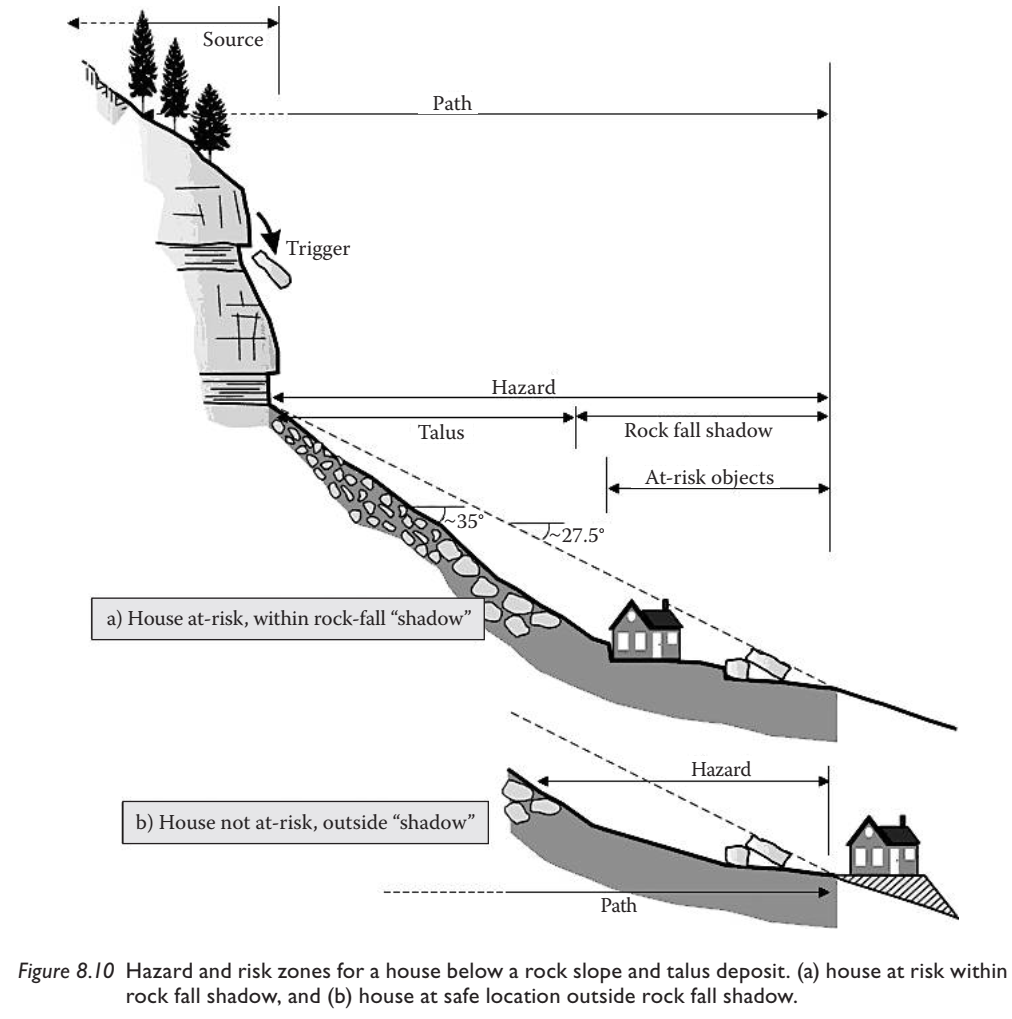

Rockfall protection system

People often assume that rock slopes are naturally stable and do not develop deep slip surfaces. So why is it necessary to reinforce rock slopes?

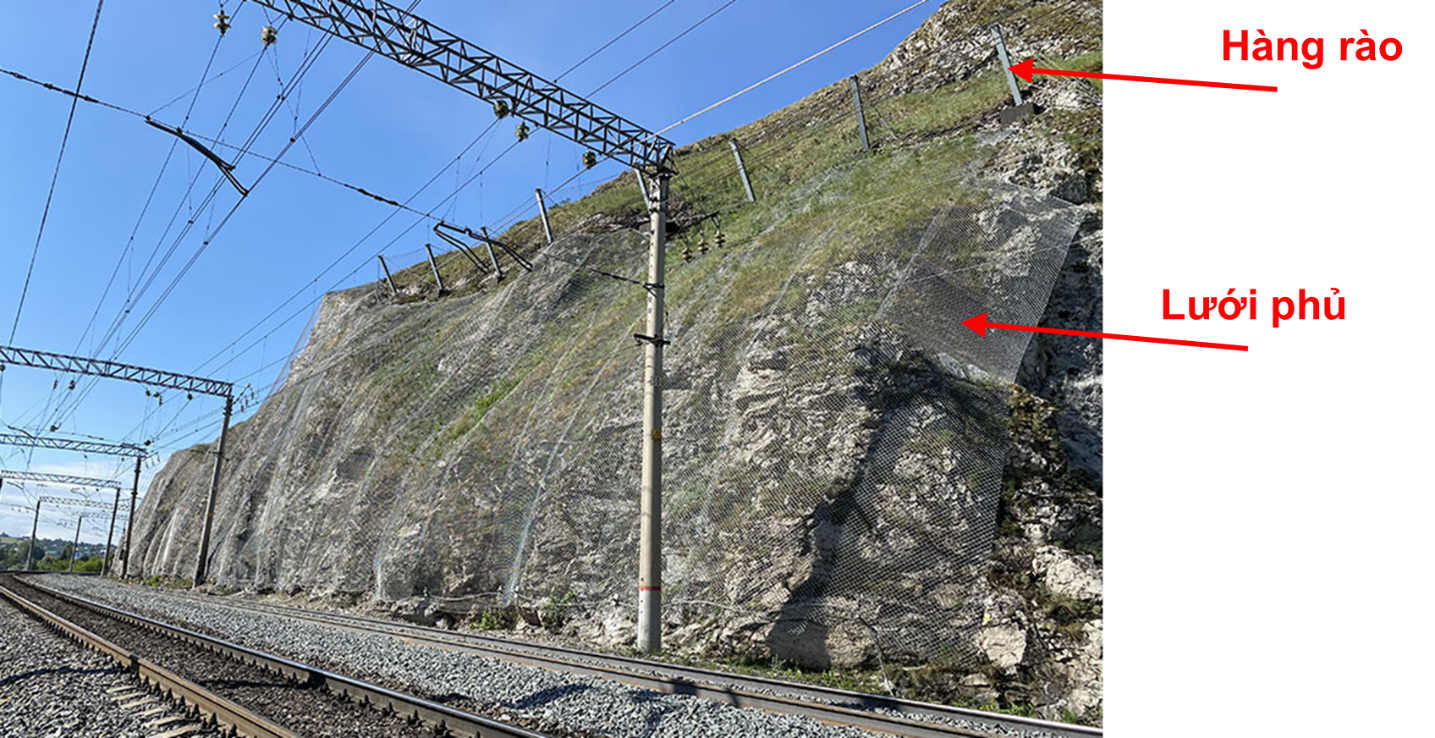

There are many reasons to pay attention to reinforcing rock slopes. One reason is that rocks often have fractures and weathering, especially at the surface, due to external influences such as water, temperature, or construction activities, as well as unfavorable rock layering. Imagine a railway or highway with a rock slope: if a rock detaches and falls into the path of vehicles, can that be allowed? Therefore, it is crucial to ensure the stability of rock slopes and to conduct thorough assessments to meet safety requirements.

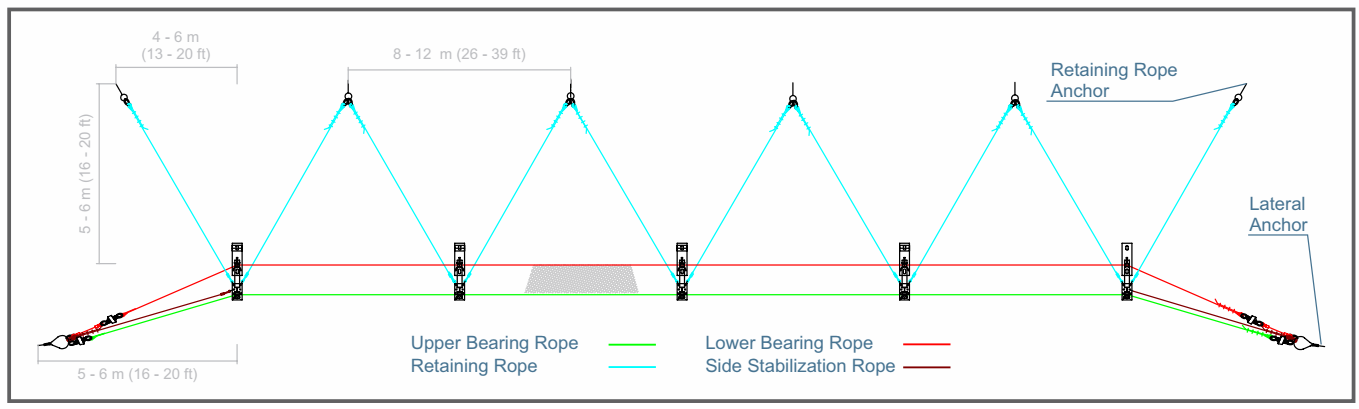

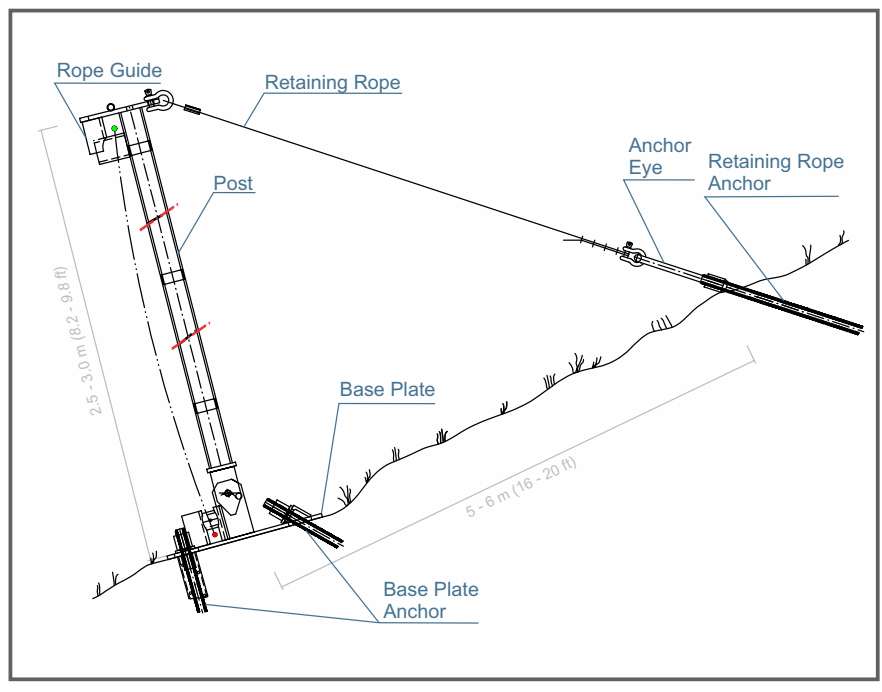

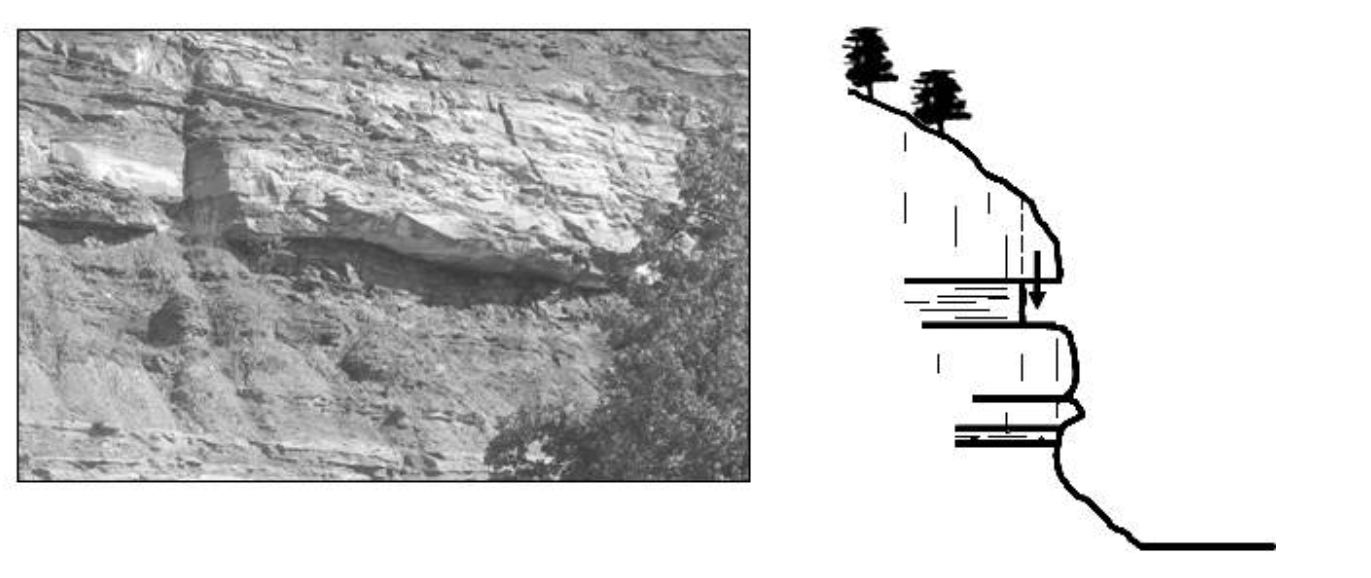

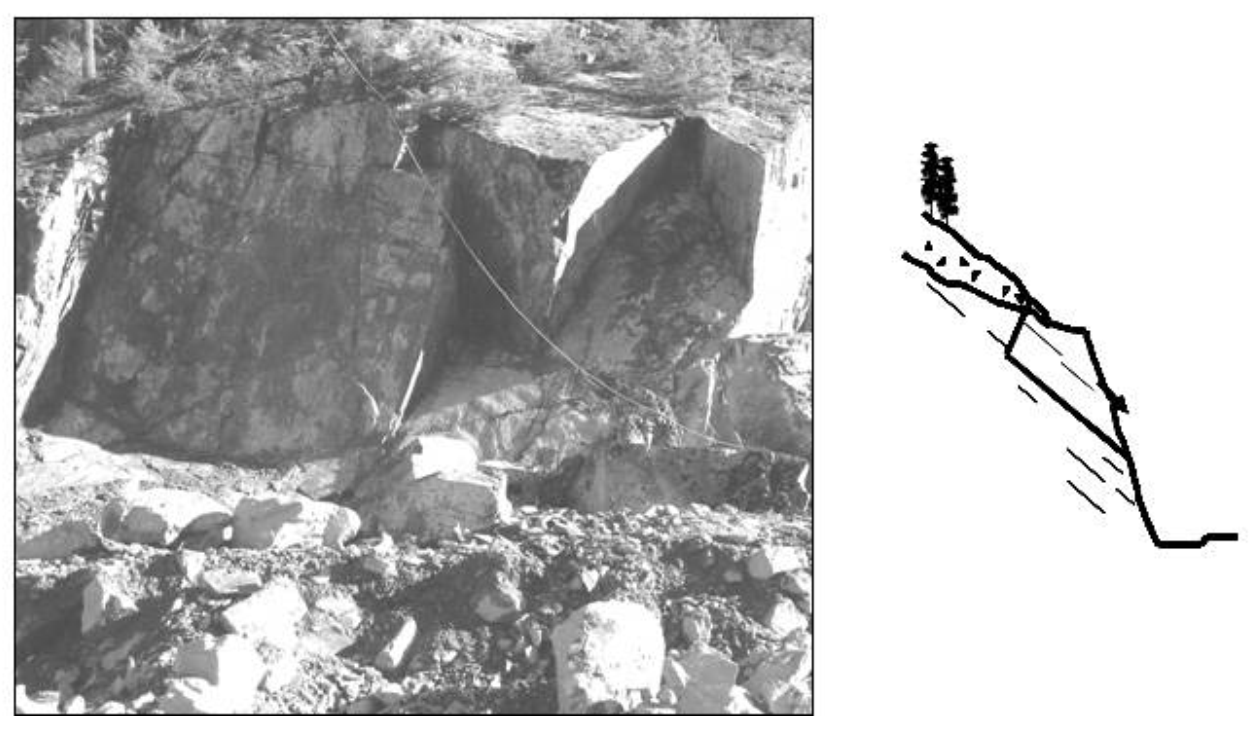

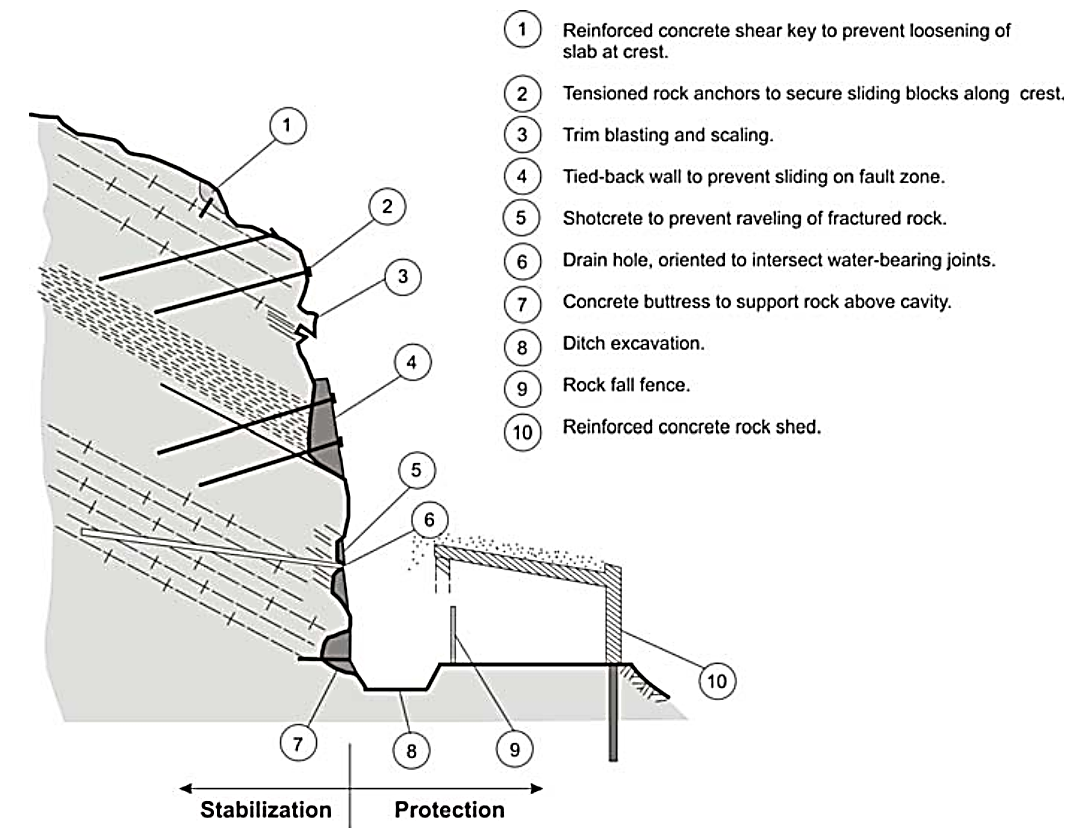

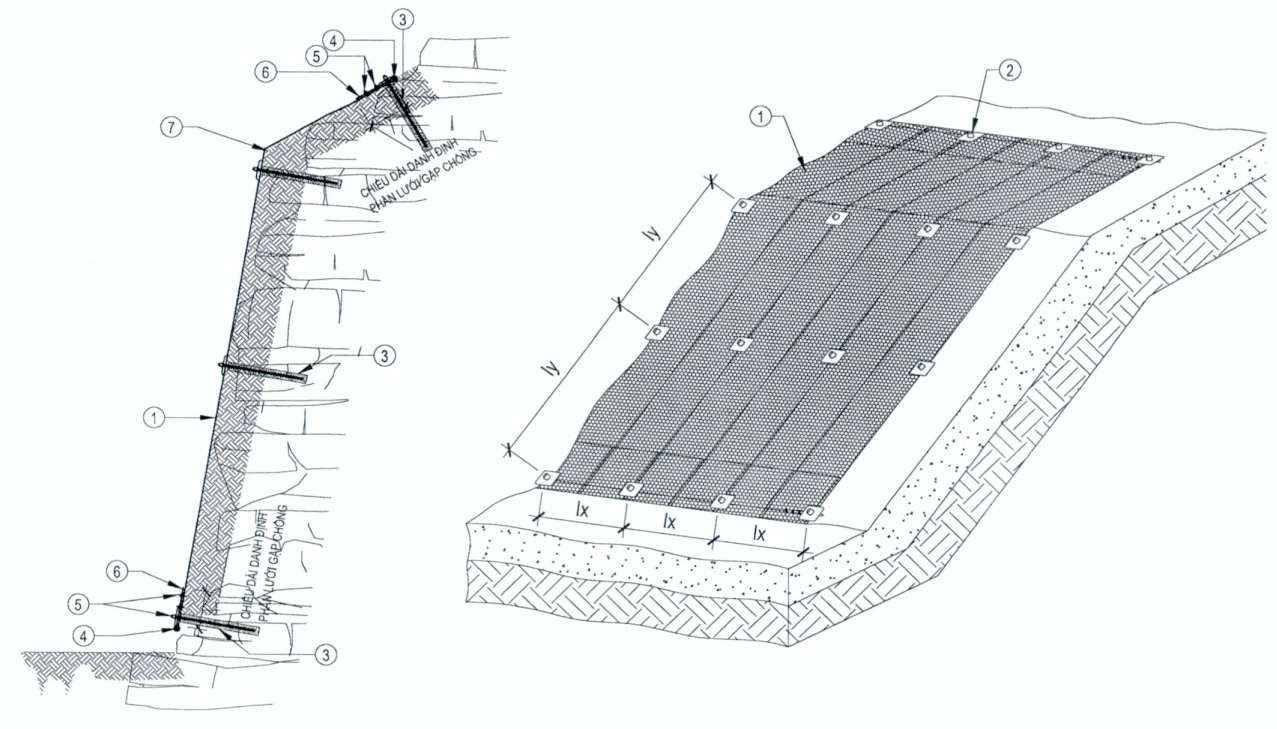

Measures for preventing rockfall are illustrated in the figure below:

1. Fence structure diagram

![1]()

![1]()

2. Rock slope reinforcement mesh structure diagram

Reinforced soil wall

Reinforced soil wall