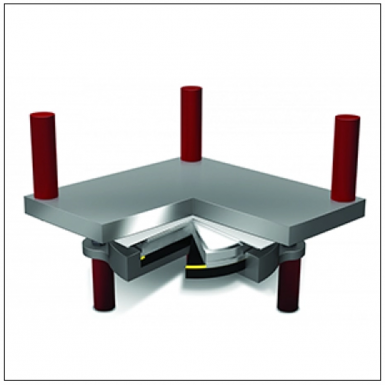

STEEL POT BEARING

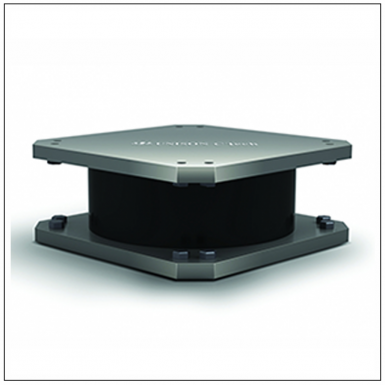

Pot bearings includes 3 main components :

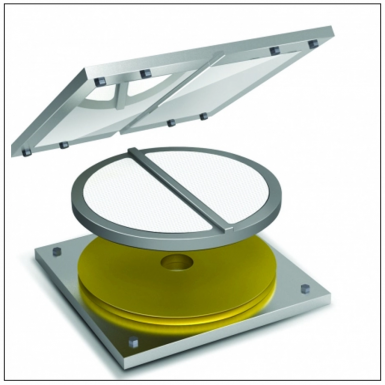

Top plate can be designed with stainless sliding plate or guiding bar, can be to absorb horizontal displacement of the structure.

The bottom plate has a pot-shaped structure with a rubber disc inside, the rubber disc is pressured from the plunger and the upper plate. With this structure, the rubber disc always has a constant volume under compressive stress, so there is no phenomenon of the rubber disc being deformed under load. The rubber disc inside the bearing is protected against gall by a pressure ring.

The piston is fitted to the rubber plate and bottom plate, with a PTFE slide movable bearing mounted on top of the piston, to increase load carrying capacity PTFE slides are normally embedded in the piston face to about ½ of the total thickness of PTFE. The bottom of the upper plate is fitted with a slide made from Ni-Cr stainless steel. The specially constructed PTFE sliding surface has recesses on the surface containing lubricating grease that is gradually released during the bearing's operation to ensure the required coefficient of sliding friction.

Details

The product has a very simple design including a pot plate, a rubber disc inserted into the lower plate, a piston that is fitted with the lower plate and a rubber disc.

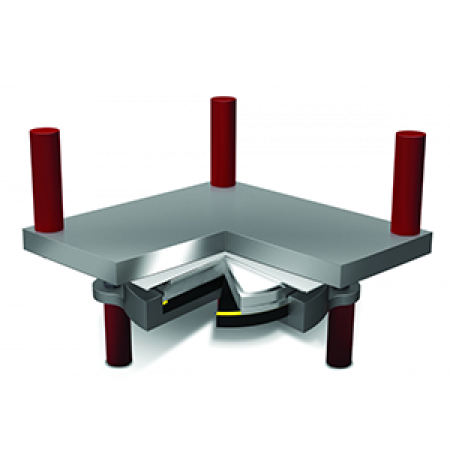

Allows displacement in two directions x & y. Not subject to external lateral loads.

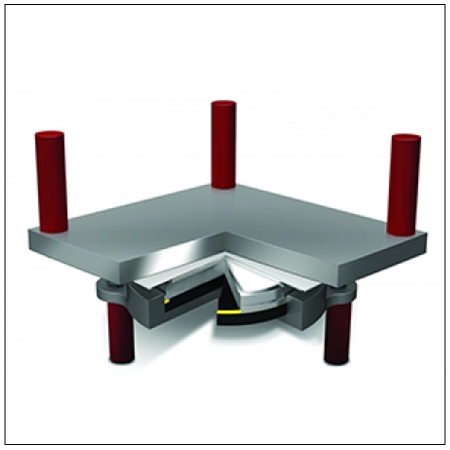

The bearing allows displacement in one direction through the guide bar. The guide bar transmits the horizontal load from the slide to the piston and further to the lower plate board. The rubber disc has no effect on dissipating horizontal forces.

Manufactory can supply one way bearings with inward or outward guiding configurations depending on the specific project.

Product Reviews